Gas treatment systems

Associated petroleum gas (APG) is an oil-dissolved gas. An associated petroleum gas is produced during crude oil production, it is by-product in fact. But APG itself is a valuable raw material for further processing. The problem of APG utilization exists as much as there is crude oil production. Special attention was given to it by the resolutions of the Government of the Russian Federation dated January 1, 2012 on implementation of the metering system, increase of environmental fines, etc.

LLC «Interenergo Stroymontazh» is a manufacturer of the gas conditioning equipment that can be widely used for APG utilization.

The team of our designers has accumulated a unique experience in design and manufacture of the gas conditioning units and APG-operated booster compressor stations.

Operation with such gas type is characterized by variation of the C3+ hydrocarbon content between 100 and 600 g/m3, and APG composition and amount is not a constant value. Both seasonal and single variations are possible (normal change of values up to 15%). Therefore, during design of the equipment it must be borne in mind the whole set of initial data:

- unstable gas composition;

- severe climatic conditions;

- heightened attention to reliability of the equipment;

- high requirements to selection of the materials and components.

With our experience, we not only comply with the requirements of the customer's questionnaires, but we are also ready to share our knowledge, which allow to optimize the equipment by reduction of its cost and by increase of its efficiency at the same time.

Our products:

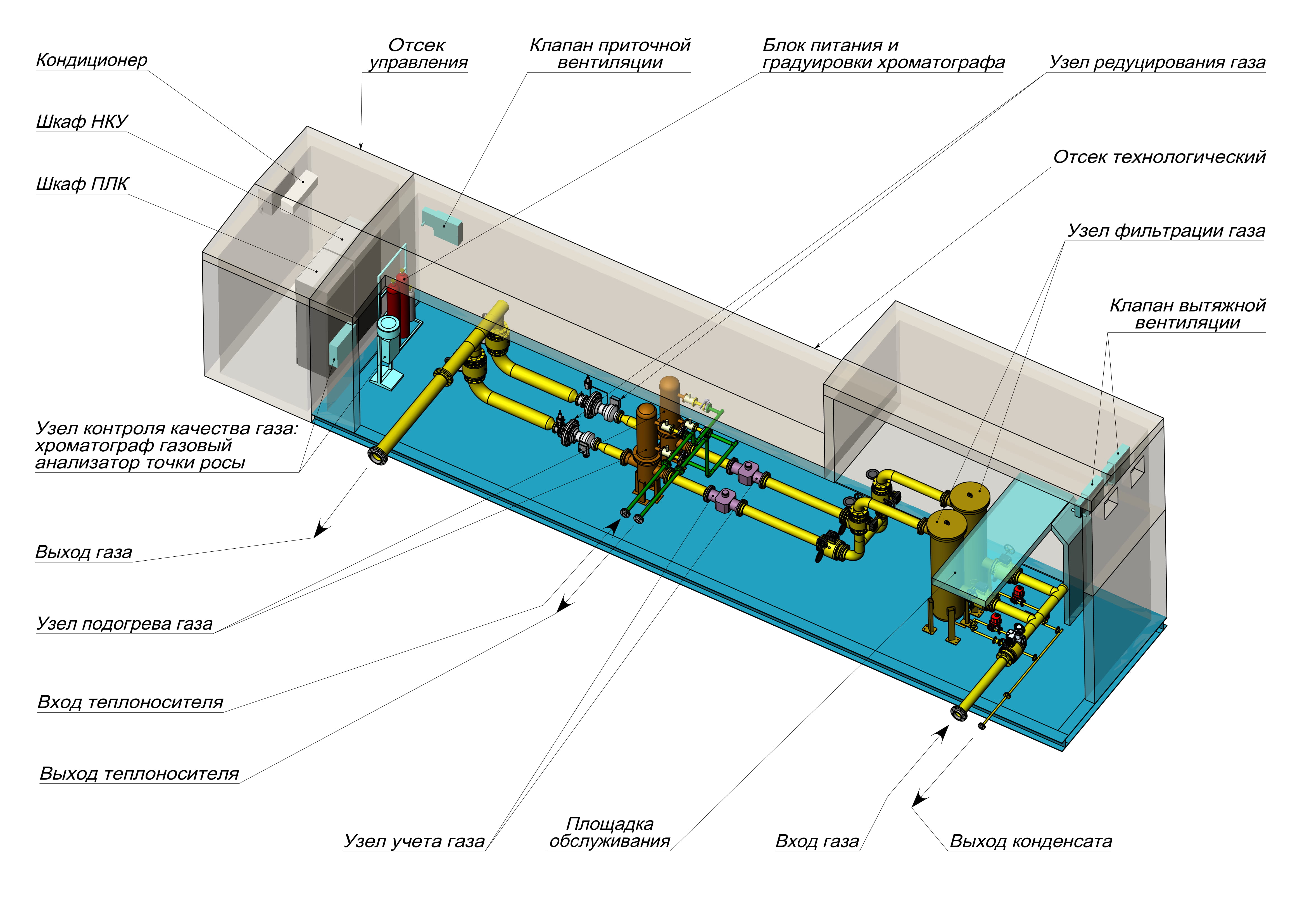

1. Gas conditioning facilities (GCF)

Use:

on the deposits, with the BOP power centers based on gas-turbine thermal power plants or combined cycle gas turbine power plants; intended for gas pre-conditioning before supply to the turbines and boiler houses;

at the compressor stations to provide the compressor department including the gas turbine gas compressor units with fuel, starting and instrument gas.

Purpose:

- intake of breakaway release of liquid;

- gas filtration of mechanical impurities and liquids;

- reduction with subsequent heating (if required);

- ripple smoothing of the gas mixture;

- commercial or process-oriented gas metering.

Design:

1) in easy-to-assemble shelter;

2) container configuration or arctic service.

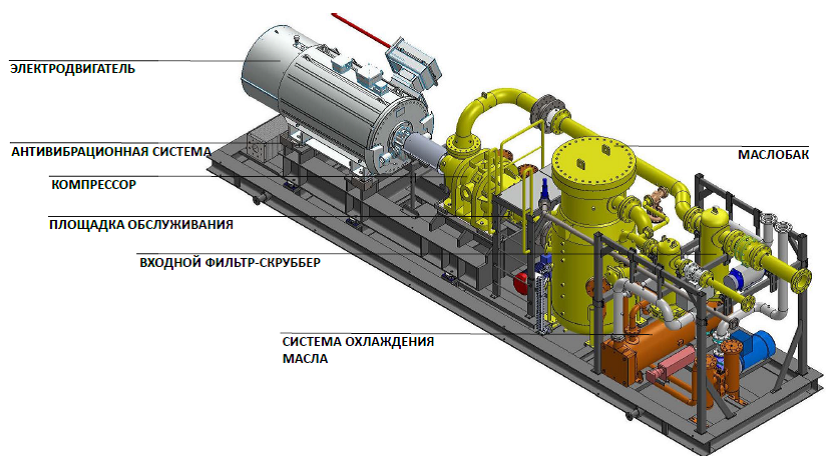

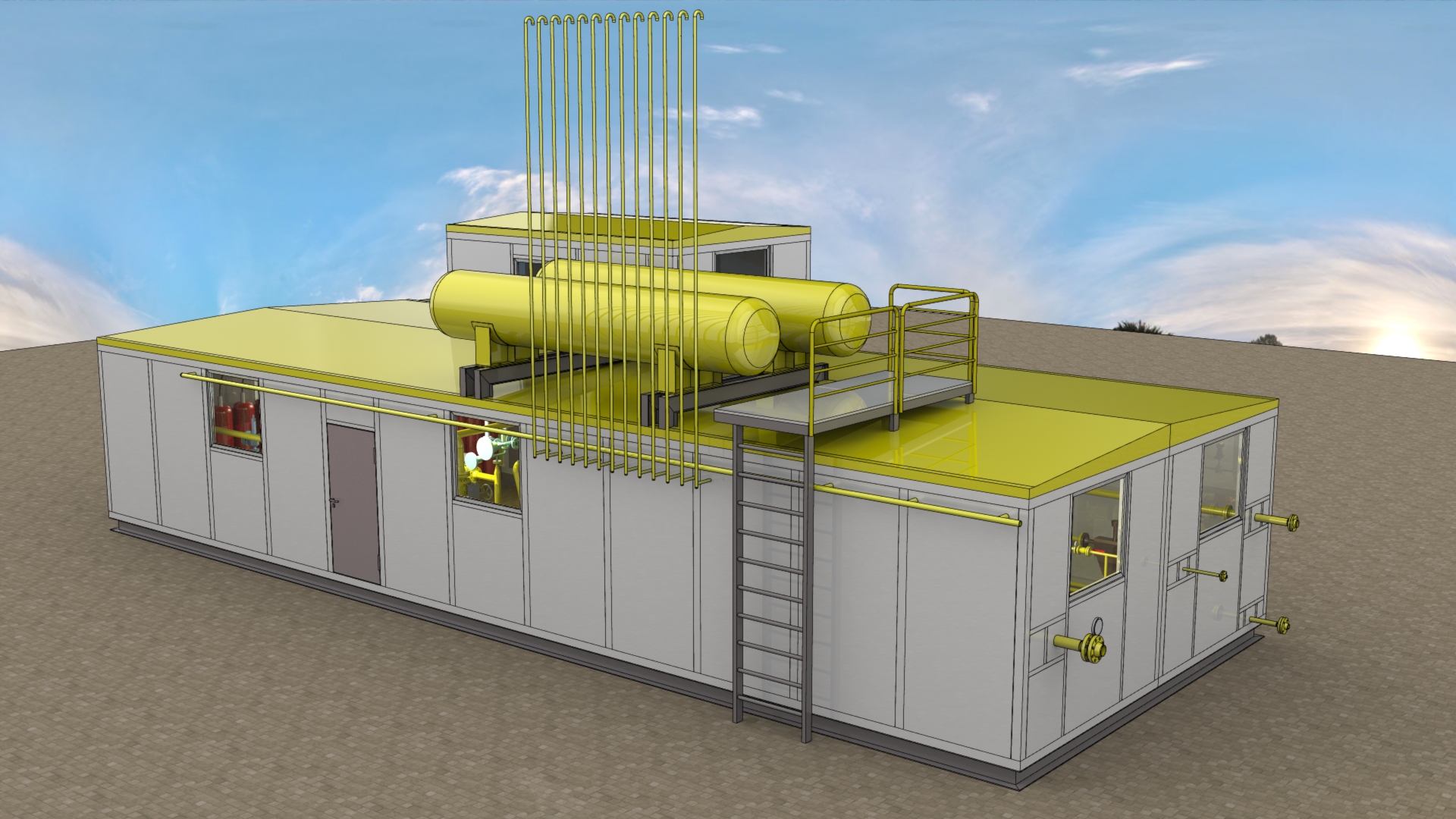

2. Booster compressor stations (BCS)

Use:

for conditioning and pumping of low-pressure (up to 0.5 MPa) associated petroleum gas.

Purpose:

1) gas collection for further gas transport in the pipeline;

2) conditioning of APG as a fuel for the BOP power centers based on gas-turbine thermal power plants or combined cycle gas turbine power plants on the deposits;

3) APG flood to increase crude oil production.

Capabilities:

- operation with aggressive sour gases;

- operability of the compressor units at very low inlet pressures;

- operation of the compressor units in their own shelter in severe climatic conditions;

- handling with heavy associated gases (density up to 3 kg/m³).

Types of BCS:

1) screw compressor units;

2) centrifugal compressor units;

3) reciprocating compressor units.